You’ve heard negative stories about aluminum wiring, which might be true. Since I can’t read your thoughts, this post will debunk myths and provide answers.

The bad news is that solid aluminum wire is not good for branch circuits. Many houses still use aluminum wire for stoves and main power.

Solid aluminum wiring has many downsides, including rust and creeping. Aluminum wires are unsafe and can cause arcing, leading to house fires. Although aluminum wiring can be risky, there are ways to reduce these risks and use it in your home.

To answer whether aluminum is suitable for electric wiring, let’s see where it all started.

First, forget the controversy; aluminum has a rich electrical wiring story. Of course, it is not as decorated as copper, but it is worth mentioning.

Is Aluminum Wiring Safe? Common Problems and Safety Issues

Many homeowners and homebuyers wonder if aluminum wiring is safe. Unfortunately, no, unless you’re speaking of multi-stranded wire.

Aluminum has several issues that make it a less attractive wiring option. Many homes started using aluminum and discovered these issues. These are three of the common problems that affect aluminum wiring:

Aluminum Wire is Prone to Aluminum Oxide

Aluminum has drawbacks in electrical applications. Copper has more resistance and needs larger wires to carry the same electricity. Because aluminum conducts heat better, we must space its connections further apart.

As the metal heats up and oxidizes, it gets more damaged and has higher electrical resistance. Aluminum oxide is very resistant to electricity, which creates excessive heat and connection issues.

But copper forms a green patina, yet it remains conductive to electricity.

Aluminum is Softer than Copper

North American houses introduced aluminum branch circuit wiring in the mid-1960s. Copper was costly, and aluminum was a cost-effective alternative. Contractors chose aluminum wiring because it is cheaper, lighter, and more flexible than copper. Which also meant aluminum was softer than copper.

Aluminum branch circuit wiring needs a bigger wire because it conducts electricity less than copper. When aluminum gets hot, it expands and then shrinks as it cools. Connections in breakers, wiring, outlets, switches, and light fixtures can become loose.

Aluminum Wire is Prone to Loose Connections

When electricity travels through the wire, it is heated up. In the case of aluminum, its loose wires tend to overheat because of its disposition.

If the wire contracts and expands, the connections may loosen. This can cause the wire to come out from under the screws, leading to arcing aluminum circuits. As a result, aluminum wiring would trip breakers or, worse, cause house fires.

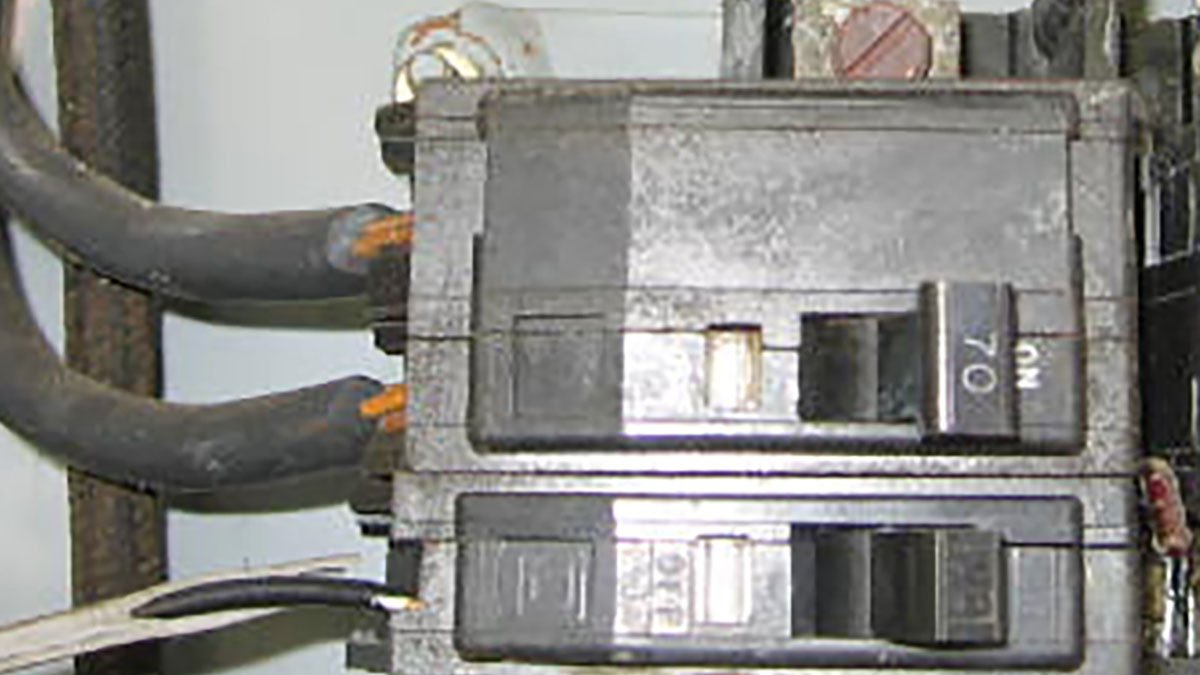

But aluminum was also used for bus bars inside older brands of electric panels. When an arc or overcurrent occurred, the bus bars would melt and fuse breakers to the bar. As a result, the circuit breakers would fail to trip. The main culprit was Federal Pacific Electric. Zinsco and other panels also had problems.

Is Aluminum Wiring Bad?

In the realm of electrical wiring, aluminum has gained a bad reputation, and it’s with good reason. People use copper more than wiring because it conducts well and is reliable. Copper prices and the good performance of copper conductors have made copper popular in electrical systems. It is a preferred choice for many uses.

According to the CPSC, around two million homes and mobile homes in the US have had aluminum wiring since 1965. A house with aluminum wiring is 55 times more likely to catch fire than others, let’s say, with copper wiring.

Even so, the idea of electricity at home is a fire hazard regardless of the material used. Builders used aluminum wiring in most homes from 1965 to 1972, as we mentioned before.

Aluminum wiring significant risks stem from the connections. Installing the wrong receptacles and aluminum conductors raises the risk of electrical fires.

Connecting aluminum wiring to boxes’ switches, outlets, or wires can cause problems. Considering how many electrical connections your home has, you realize risks are involved.

The signs we pointed out earlier make the problems easy to see. These signs include hot cover plates, lights that flicker, and overheating. Overheating is the primary cause of fires by aluminum wiring. The coating on wires can deteriorate over time because it can overheat more than copper.

Other factors can also cause overheating in solid aluminum wires. Again, its lightweight character contributes to its quicker wear and tear. The houses with aluminum wiring are 50 or more years old; thus, the wear could be extensive.

If you find a house with aluminum wiring, take proper precautions to reduce risks because opening walls to replace the aluminum wiring is costlier than the alternative.

Is It Okay To Buy a House With Aluminum Wiring?

We have found problems with aluminum wiring that can be risky when buying or selling a house. You can buy a home with aluminum wiring if you consider the following first:

- To check the wiring in your possible new home, get advice from a qualified electrician. They can observe the extent of the tear and whether you need to replace some installations. Their main task is to inspect the wiring and aluminum connections for major issues.

- The electrician report should determine your next move. If they recommend a replacement, come up with the cost for the entire rewiring. We will run the new copper wires across each branch circuit in this case. Remember, buyers may use this during home negotiations.

- To avoid any potential risks, do not overload the wires. We should distribute the electrical loads among the many cables in use. Under normal circumstances, aluminum overheats from continuous thermal expansion and contraction. Can you now imagine what would happen if one wire becomes overloaded? You get the picture; that’s a potential fire hazard condition.

- You need to know the insurance costs for a house with aluminum wiring. Insurance companies have a problem with ensuring homes with aluminum wiring. If so, you can shop for an insurance company to cover your home.

Should You Replace Existing Aluminum Wiring?

Several issues with aluminum wiring are hard to ignore. Many homeowners feel better knowing their wiring is over 50 years old. In normal circumstances, that is a commendable achievement.

Aluminum wiring mitigation involves reducing the risk of fire hazards associated with older aluminum wiring in residential properties. This process includes inspections, repairs, and rewiring with copper to improve safety and reduce the likelihood of electrical issues.

Replacing your wiring is the best solution because it served you well for a long time but has potential risks. You replace the aluminum wiring with copper wiring. Even so, there are considerations you need to make before settling on a replacement. Here are some of them:

- Aluminum wiring replacement does not come cheap. You have to pay the workers to remove the old wiring and install the new one. You also have to cover the cost of materials and tools.

- The replacement process can be tedious. Since the process is quite rigorous, it might force you to remodel your house. While this is not a disadvantage per se, some homes are best left as they are. Remember, these homes still have fixtures or designs from 50 years ago you would want to retain. It could be that’s what attracted you to the house in the first place. However, if the aluminum wiring calls for remodeling, you may remodel it.

- Forfeiture of insurance. Because of bad press, many people avoid it, and insurance companies rarely cover homes with aluminum wiring. Replacing your aluminum wirings may also remove the insurance that comes with it.

Aluminum got negative attention, but it couldn’t beat copper for electrical wiring. Manufacturers and authorities found issues with aluminum and searched for a solution.

Some of the solutions they found improved the performance of aluminum. They even created a better-performing aluminum alloy. The only problem was that they discovered the answers too late.

By then, most people had dropped aluminum as a choice in wiring. Manufacturers had a hard time marketing aluminum to the masses. This explains the myths associated with the presence of aluminum wiring.

Homeowners wanted to save money, so they kept their wiring and used new solutions. But sellers should remember that aluminum wiring might discourage potential home buyers.

Additional Repair Options for Aluminum Wiring

The bottom line is that remodeling is the best solution, so go for it. But, if you wish to check out other options aside from replacing aluminum wiring, I compiled some of them for you:

1. The Best Option is to Rewire the House

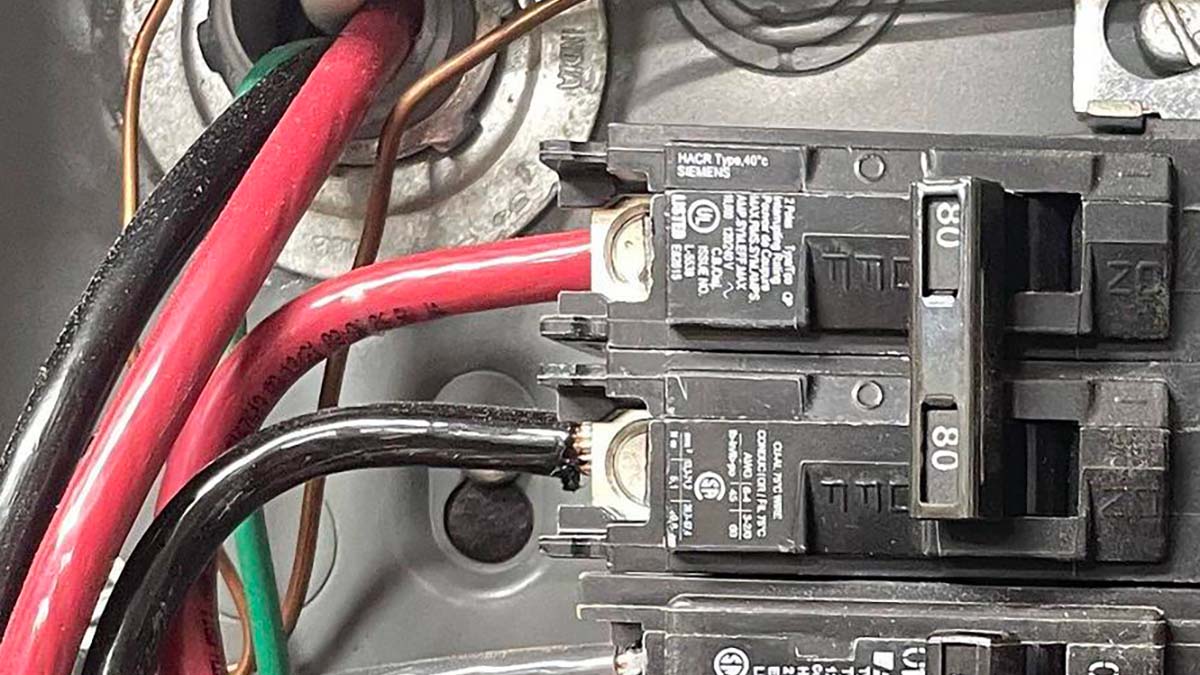

The best option for repairing aluminum wiring is also the most costly. Replacing the house’s wiring with copper wires can be costly. The total expense depends on the number of circuits that must be replaced. Other updates to the electrical panel will also be a rule if you choose to rewire the house.

While you get to dig deeper into your pockets, this is an ideal solution for your home. On average, it can cost you between $15,000 to $35,000 or more. An experienced electrician can help you find the correct number for your new home.

2. You Can Replace All Outlets with Dual Rated Outlets

To improve the safety of aluminum branch wiring, switch outlets, and switches with dual-rated ones (CO/ALR). But you must still use special connectors to join copper and aluminum wires.

3. Pig Tailing Copper Wire to Aluminum Wiring Safe

There is a cheaper alternative for consideration. You can pigtail a piece of copper wire to the end of each aluminum wire using special connectors. It’s a standard repair method in such situations. From the previous observation, aluminum wiring weakness is worse at outlets and switches.

Connect a copper wire to an aluminum wire, omitting pig tailing. But, you should be aware of the potential hazard associated with poor connections in electrical systems. Most local authorities don’t allow copper pigtails because of safety concerns. Before you start fixing anything, talk to electricians to make sure the information is correct and follows the rules.

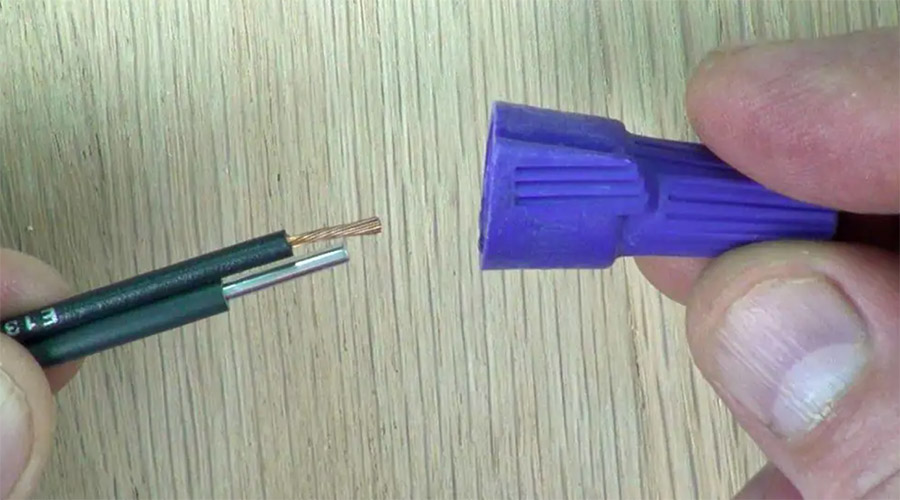

You can’t make pigtail copper and aluminum wire connections with standard wire nuts. You must use approved wire nuts or connectors that are Al/Cu rated. Connections safe include:

Twister Al/Cu Wire Connectors are wire nuts that connect copper and aluminum wiring. The Al/Cu rating identifies them, and they are purple.

Copper Aluminium Connectors (COPALUM) are special connectors used for pigtail repairs. The U.S. Consumer Product Safety Commission (CPSC) approves them.

This electrical repair is a lasting fix. A professional electrician uses a special twist-on connector to attach the pigtail. Special tools use pressure to connect aluminum and copper.

After achieving a connection, apply a heat-shrink insulator. Ensure that it’s the only authorized person that performs this action.

AlumiConn Connectors – This method has been around for 15 years now. The CPSC suggests using this method instead of the COPALUM.

Unlike the COPALUM, the AlumiConn uses a collection of terminal screws to link with the pigtail repair. You need to tighten the screws as the manual indicates for the best results. If done, the tight screws will offer a safe and long-term solution you may rely on.

You must connect the electricity at each junction box, breaker, outlet, switch, and fixture. Rewiring with copper wire is the safest and most permanent repair option. This is because there are a lot of aluminum electrical contacts, and it’s possible to miss even one bad connection.

Issues with Homeowners Insurance and Aluminum Wiring

Most insurance companies don’t cover homes with aluminum type of wiring because it’s challenging. You’ll have to shop for an insurance company that covers homes with aluminum wiring connections.

To make getting aluminum wiring insurance easier, begin by doing the repairs mentioned earlier. After that, you can get the paperwork to show you did the repairs right.

On the flip side, if you are selling a home, it is better to do the necessary repairs before putting the house on sale. The potential buyer knows that someone has done the repairs. Homebuyers may worry about repairs if the homeowner’s contractors use aluminum wire.

Furthermore, the certification you receive will make it easier to get homeowners insurance. When you do the repairs in advance, they hurry to close the deal.

Buyers cancel the contract after the inspection, especially if they don’t know the solutions. Plus, they could be avoiding the aluminum wiring repair problem altogether.

Before buying a home with original aluminum wiring, talk to your insurance agent to see if they can insure it. The bottom line is that doing the repairs is good for business.

When Did Construction Start Using Aluminum Wiring?

Someone invented electricity in the 1800s, and people began using it. The inventors knew copper was an excellent electrical conductor of heat from the start. Even when wiring at homes became a thing, people adopted copper earlier.

Some dissimilar metals or elements are also good conductors of heat; aluminum is one of them. But aluminum pales in comparison with copper. A few changes allow aluminum to perform almost as well as copper.

In the 1960s, when copper was hard to find, aluminum wiring became popular in North America. Aluminum became a cost-effective option. But, aluminum faced several issues that required correction.

Builders made changes due to customer complaints about using aluminum too much. Among the manufacturers’ changes was to use a larger wire than the one used in copper wiring.

In a real sense, aluminum packs a 12 gauge wire while copper packs a 14 gauge one. And for your information, a 12 gauge wire is larger than a 14 gauge electrical wire.

Aluminum has several problems after widespread adoption. Overheating was one of the significant issues that riddled aluminum wiring. Other issues include warm cover plates on receptacles and switches and flickering lights.

Aluminum Wiring FAQs

Below are answers to your most frequently asked questions (FAQs).

Is it OK to buy a house with aluminum wiring?

Buying a house with aluminum wiring can pose safety risks. It might lead to higher insurance premiums and potential repair costs. Before purchasing, have the wiring inspected by a licensed electrician. Be aware of the risks and associated expenses.

Should aluminum wiring be replaced?

To determine if you should replace aluminum wiring, consider safety, local rules, insurance, wiring condition, average cost, and peace of mind. If signs of corrosion or damage exist, replacement might be necessary. Cheaper, acceptable repair options are available.

How serious is aluminum wiring?

Aluminum wiring is not dangerous, but problems can occur with connections and if it’s old. Homes with aluminum wiring need inspection by an electrician who knows about aluminum wiring problems. They can check its condition, find dangers, and suggest the proper fixes.

Do you need special outlets for aluminum wiring?

Yes, if your home has aluminum wiring, use devices designed for aluminum or aluminum and copper. These electrical devices are often labeled “CO/ALR,” meaning “Copper/Aluminum Revised.”

Final Thoughts

If you plan to buy a home with aluminum wiring, you may solve the problem using our discussed methods. The main worry for aluminum is not the wires but the electrical connections at outlets and switches.

It is important to inspect the electrical currents at these outlets and switches. We must also check if they are compatible with the electrical service panel. This will help us address any potential issues with aluminum wiring.

Some cheaper ways to fix it involve adding copper wires at the connection. Once you put up these solutions, your home is safer. Aluminum wiring overheating is a cause of fires.

The other question people ask is whether it is okay to buy a home with aluminum wiring. Buying a home with aluminum wiring is okay if you consider the repair or replacement costs.

The home seller should conduct the potential repairs before selling the home. One of the disadvantages of aluminum wiring is the lack of insurance. Most insurance companies refuse to insure aluminum wiring in homes. You’ll have to shop around before you can get a willing one.

Copper usage is widespread because it is superior to aluminum in more ways than one. Its ability to conduct electricity well, its durability, and its safety features make it a popular choice for electrical use.

But, even though it has advantages, many homes still use aluminum wiring. This is because copper is expensive, and there are additional costs for installation and rewiring.