According to the NEC, the wire size for 200 amp service is a 3/0 AWG copper wire or 4/0 AWG aluminum wire. You should increase wire size by 20% for every extra 100 feet run to account for voltage drop.

For a 200-amp cable size spanning over 200 feet, choose a 500 kcmil copper wire or a 1000 kcmil aluminum wire. Check the table below for the correct gauge and distance.

Understanding the intricacies of what size wire for 200 amp service is paramount for homeowners and commercial building managers alike. This electrical service can handle a maximum load of 200 amps, making it a popular choice for modern residential properties and commercial spaces that house numerous appliances and electronics.

The ampacity of a 200 amp service denotes the maximum amount of electrical current that the main service panel can safely distribute across various circuits.

Selecting the appropriate wire size for a 200 amp service is not just a recommendation—ensuring safety and efficiency is necessary. The wire size for 200 amp service acts as the lifeline of your electrical system, carrying the substantial electrical load to power everything from lighting to heavy machinery in commercial settings.

It’s crucial to adhere to the guidelines set by the National Electrical Code (NEC) to avoid potential hazards and ensure that your electrical system operates at its peak efficiency.

Whether installing a new service or upgrading your existing setup, understanding the wire size for 200 amp service is the first step towards a safe and efficient electrical system.

Our electrical panel cost calculator can help estimate the cost of 200 amp upgrades.

Cable Types and Their Applications

When planning a 200 amp service, selecting the correct cable type is crucial for ensuring your electrical system’s safety, efficiency, and longevity. The choice of cable not only impacts the performance of your electrical setup but also influences its durability and maintenance needs.

THHN/THWN Wires

- Characteristics: THHN (Thermoplastic High Heat-resistant Nylon-coated) and THWN (Thermoplastic Heat and Water-resistant Nylon-coated) wires are renowned for their durability and heat, moisture, and oil resistance.

- Applications: These wires are extensively used in conduit and cable trays for services, feeders, and branch circuits in commercial or industrial applications. They are ideal for exposed and concealed work in locations that may be dry or wet.

- Advantages: The nylon coating of THHN/THWN wires offers additional protection against physical damage. They are also flame retardant, enhancing the safety of your electrical system.

Service Entrance SER Cable

- Usage: Service Entrance Cable (SER) is pivotal in connecting the electric meter to the main service panel. It is primarily used to transport electricity from the service drop to the meter base and subsequently to the distribution panelboard.

- Specifications: SER cables come in various sizes and are typically composed of aluminum or copper conductors insulated with robust jackets like XHHW-2, THHN, or THWN.

- Considerations: When choosing an SER cable, it’s essential to consider the environmental conditions it will be exposed to, such as sunlight or moisture, to ensure the insulation and overall construction are suitable for the intended application.

Underground Service Entrance (USE-2) Cable

- Design: USE-2 cables are specifically designed for direct burial applications and are commonly used when the service entrance conductors are routed underground from the electric meter to the main service panel.

- Material: These cables are generally made of aluminum or copper, with insulation materials adept at withstanding heat, moisture, and the rigors of direct burial conditions.

- Direct Burial Applications: USE-2 cables are robust and versatile, suitable for all outdoor applications and direct burial installations. They are engineered to endure various environmental conditions, making them an ideal choice for underground use.

The wire size and cable type you choose are pivotal in ensuring that your electrical system is compliant with the NEC and tailored to the specific needs of your residential or commercial building. The right cable service, be it THHN/THWN, SER, or USE-2, will provide a reliable and efficient electrical infrastructure that stands the test of time.

Choosing a Wire Size for 200 Amps

For underground installations of a 200 amp wire cable, use a PVC conduit of at least 1.5 inches in schedule 40 or 80. When running three wires within the same conduit, use a larger size of 2 or 2.5 inches.

Electricians often use 4/0 AWG aluminum wire for long distances to save money on copper. For underground 200 amp services, it’s best to use a 250 kcmil aluminum wire. This wire has a 255A ampacity, enough to meet the minimum requirement of 250A.

A 200a wire is safe and can handle high current demands for your system. Learn the electrical codes to choose the correct wire size for your 200 amp service.

You must get an electrical permit when starting a 200-amp service wiring project. A skilled electrician should install the equipment according to local codes to keep things safe.

The power comes from the utility service entrance. It goes into the outdoor electrical meter base. Then, it goes into the main electrical panel in a garage, basement, or room.

Is 2/0 AWG Copper Wire Good for 200 Amps

In some cases a 2/0 AWG copper wire is suitable for a 200 Amp electrical service. The 2/0 copper wire will be at maximum capacity (195 to 200 amps) and should only be used for short distances like 50 feet to not be affected by voltage drop.

To account for the NEC 80% rule, it’s safer to use the recommended 3/0 copper wire or the 4/0 aluminum wire.

Related Reading: How To Wire A 100 Amp Service Panel

AWG Wire Gauge Sizes for 200 Amperage

The American Wire Gauge (AWG) system determines the size of electrical wiring in the US.

AWG guidelines state using 3/0 copper wiring or 4/0 aluminum or copper-clad wiring for a 200-amp service rating. Your choice of wire depends on the voltage drop and the wiring length.

The term “aught” indicates cable wiring sizes larger than #1 in the United States.” This term comes from the word “naught,” which means zero. People use it to describe larger wire sizes.

- 1/0=0

- 2/0=00

- 3/0=000

- 4/0=0000

- The cable wiring sizes after 4/0 correspond to their circular mil area, measured in thousands.

A #3 copper wire is suitable for up to 80 amps. On the other hand, a 3/0 copper wire is ideal for up to 200 amps.

A #4 aluminum wire is suitable for up to 50 amps. On the other hand, a 4/0 aluminum wire is ideal for up to 200 amps.

You’ll need to use a thicker gauge wire for longer runs. When runs exceed 100 ft, switch to kcmil wire diameter to cover greater distances.

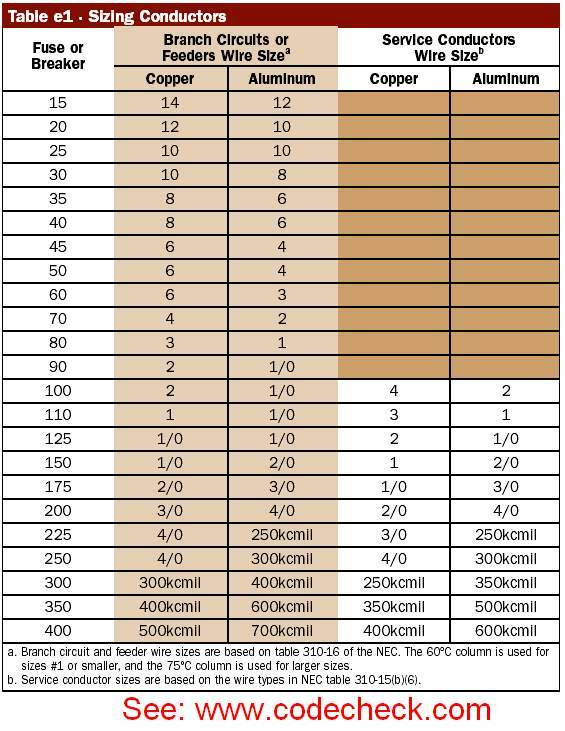

National Electrical Code Requirements Table 310.12

The following wire size chart from National Electrical Code specifications reflects amps, wiring size, and conduit size for copper, aluminum, and copper-clad wiring:

| Service or Feeder Rating | Copper Wire | Aluminum or Copper-Clad Aluminum Wire | Minimum Conduit Size |

|---|---|---|---|

| 100 Amps | 2 AWG | 1/0 AWG | 1.25 inch |

| 110 Amps | 1 AWG | 1/0 AWG | 1.25 inch |

| 125 Amps | 1/0 AWG | 1/0 AWG | 1.25 inch |

| 150 Amps | 1/0 AWG | 2/0 AWG | 1.25 inch |

| 175 Amps | 2/0 AWG | 3/0 AWG | 1.5 inch |

| 200 Amps | 3/0 AWG | 4/0 AWG | 1.5 inch |

| 225 Amps | 4/0 AWG | 250 kcmil | 1.5 inch |

| 250 Amps | 4/0 AWG | 300 kcmil | 2 inch |

| 300 Amps | 300 kcmil | 400 kcmil | 2.5 inch |

| 350 Amps | 400 kcmil | 600 kcmil | 3 inch |

| 400 Amps | 500 kcmil | 700 kcmil | 3 inch |

After discussing the National Electrical Code and its importance in determining the minimum wire size for a 200-amp service, it’s crucial to consider other factors influencing your choice.

Cable length is one such factor, as longer runs may require larger wire sizes due to voltage drop. The breaker size and cable diameter ensure your system runs efficiently and safely. Sizing your wiring is not just about meeting code but also about optimizing the performance and safety of your electrical system.

You must account for the cable length when planning to wire a 200-amp service. Longer cable runs may require upsizing the wire to counteract voltage drop, ensuring your system performs at its best.

The breaker size must match the wire size to prevent overheating and danger. Calculation factors in all these elements—amperage, cable diameter, and cable sizing—are necessary to pick the correct size of wiring. This calculation ensures you meet the minimum requirements and address safety and efficiency.

Copper vs. Aluminum Wire Size Conductor

Let’s look at the difference between copper and aluminum wires. Copper works better for a longer time. But if you don’t have much money, aluminum wire is cheaper for your subpanel. Just ensure it’s the right size and put it in the right way, as the NEC says.

200 Amp Copper Wire

Let’s discuss what size copper wire for 200 amp service you’ll need.

Choose 2/0 AWG for 200 amp copper wire size. Copper is popular for wiring because it handles heat well and doesn’t rust. It’s a top-notch conductor behind silver, meaning it can carry more electricity with a thinner wire. Copper stays tight in its connections because it doesn’t stretch with temperature changes, and even when it turns green from oxidation, it still works great.

Copper wires are flexible and don’t break easily, so they’re good for long distances.

WHY CHOOSE COPPER CONDUCTORS?

- Conductivity: Copper is a highly conductive metal, second only to silver in conductivity. Its high conductivity can handle a larger electrical load so you can use a smaller gauge wire. For the same level of conductivity, copper wire is about half the diameter of aluminum wire.

- Heat Resistance: Copper wires are better at handling heat because they conduct electricity well. The copper wire doesn’t expand or contract like aluminum, which keeps cables tight on lugs.

- Corrosion Resistance: Copper is resistant to corrosion. When copper oxidizes, it can turn green but still conduct electricity.

- Malleability: Copper is good at conducting electricity, so the wire strands can be thinner and more flexible without breaking.

- Distance: Because copper conductors have high conductivity and heat resistance, they can be used over long distances.

Remember: The size of the copper wire depends on the distance and the electrical load. For a standard 200-amp service, 3/0 copper wire is fine. If you’re running the wire far, you might need a bigger gauge wire.

Aluminum wiring is also a common choice because it’s cheaper and lighter than copper.

200 Amp Aluminum Wire

Let’s discuss what size aluminum wire for 200 amp service you’ll need.

For a 200 amp aluminum wire size, you need a minimum 4/0 AWG. The cables need to be thicker since aluminum doesn’t conduct electricity as well as copper.

Today’s aluminum wires are made of many small strands, which makes them safe for modern homes.

Aluminum can become less effective over time and might cause fires if it gets too hot. But if you put the antioxidant paste on the connections, it can help stop this from happening. The National Electrical Code (NEC) says you don’t need this paste for 200-amp aluminum wires in panels.

Aluminum is less expensive than copper, so many people use it. Copper-clad aluminum is a bit better but costs more than plain aluminum. Still, both are cheaper than pure copper.

Electricians like aluminum because it’s easy to bend and light, making it quicker to install. This can save money on materials and labor.

WHY CHOOSE ALUMINUM CONDUCTORS?

Despite copper’s advantages, 4/0 aluminum wire for 200 amp service also has its merits. Aluminum wiring is advantageous because it is cheap and light, making installation easier.

- Budget-Friendly: Aluminum wire is a favorite choice due to its affordability. Aluminum conductors are cheaper to produce than their copper counterparts. Copper-clad aluminum wiring works better, but it costs more than aluminum wiring. Even so, both these options are cheaper than pure copper wires.

- Faster Installation: Professional electricians find it easier to work with aluminum because it is lighter and more malleable than other wires. It feeds well through the electrical conduit for faster installation, reducing material and labor costs.

Note: Aluminum wire connections can loosen over time, which can be dangerous. Always check to ensure they’re tight to prevent any fire risk.

Before choosing a 200 amp breaker panel, doing an electrical load calculation is a good idea.

Service Entrance and Main Service Panel Considerations

The service entrance and main service panel are critical components of a 200 amp service, acting as the primary hubs for electrical distribution in a property. Proper selection, installation, and maintenance of these components are essential for the electrical system’s safety, efficiency, and reliability. Here’s what you need to consider:

Electric Meter and Meter Main

- Role and Importance: The electric meter measures the electricity the property consumes. The meter main, which houses the meter, serves as a transition point where the utility’s responsibility ends and the property owner’s responsibility begins.

- Selection Tips: Choose a meter and meter main that are compatible with the utility’s requirements and are rated for the service size. Ensure they are weatherproof if installed outside and easily accessible for readings and maintenance.

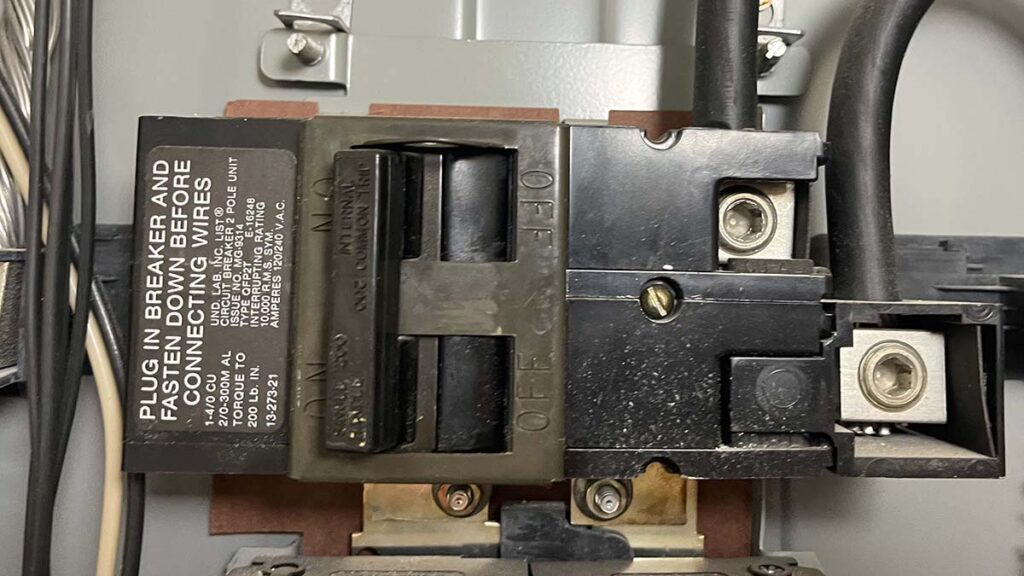

Main Service Panel

- Central Distribution Point: The main service panel is where the electricity is distributed to various circuits throughout the property. It houses the main breaker, which controls the power supply, and individual circuit breakers for different areas or appliances.

- Considerations for Installation:

- Adequate Capacity: Ensure the panel has enough capacity for current needs and potential future expansions. A 200 amp panel is a common choice for modern homes and small commercial buildings.

- Accessibility: Install the panel in a location that is easily accessible for maintenance and emergency shutoff but is away from potential hazards.

- Labeling: Clearly label each circuit in the panel for easy identification. This is crucial for maintenance and emergencies.

Tips for Ensuring Optimal Performance and Safety:

- Professional Installation: Always have the service entrance and main service panel installed by a licensed electrician. This ensures adherence to local codes and safety standards.

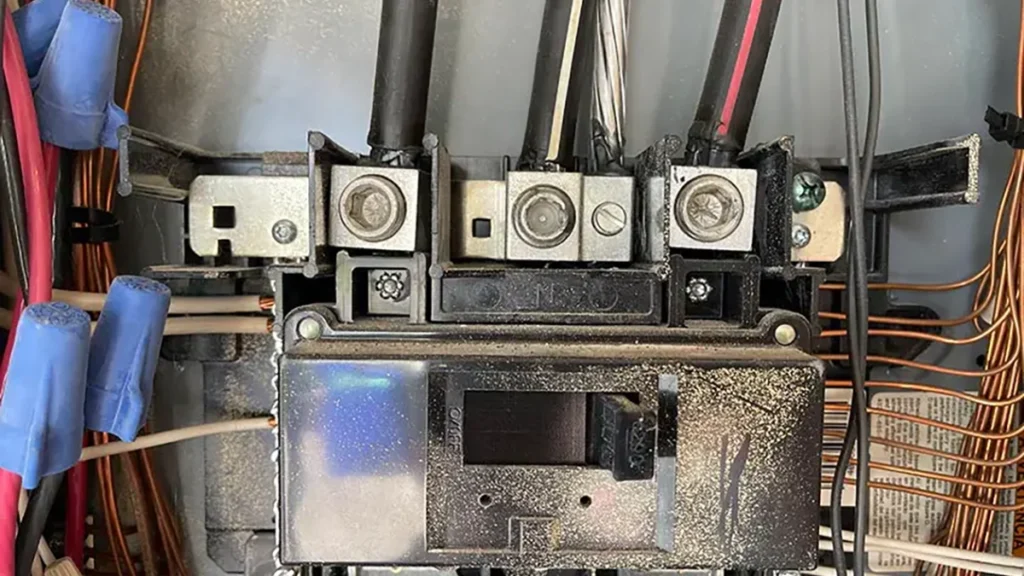

- Regular Inspection and Maintenance: Schedule regular inspections to ensure all components are in good condition and functioning correctly. Address any issues, such as corrosion or loose connections, promptly to prevent potential hazards.

- Upgrade When Necessary: If your current service entrance or panel is outdated or no longer meets your needs, consider upgrading to a newer model that can handle increased capacity and offers improved safety features.

Determining the Wire Length for 200 Amps

Find the distance between the meter base and the breaker box to determine the correct cable size.

The allowed voltage drop is 3%. Use a wire with a higher gauge to lessen voltage drop over long runs.

When choosing wire for your service entry, consider its length and whether to use aluminum or copper. Upscale the AWG or kcmil cable size for extended distances. See our 200 amp size chart below for short and longer distances.

To ensure you choose the correct wires for your amp panel, consider how much power you need and how big the cables should be.

200 Amp Cable From Meter To Panel

200 amp service wire from meter to panel is an essential component of an electrical system. It brings electricity from the meter to the main panel in your house.

The wire size for a 200 amp aluminum wire system depends on various factors such as distance, voltage drop, and temperature ratings. For residential 200 amp installations, use a 4/0 or 250 kcmil aluminum wire.

A 3/0 gauge copper wire size can handle up to 200 feet distances. A 4/0 or 350 kcmil aluminum wire costs less and is easier to run over the same distance.

You can use our Voltage Drop Calculator to calculate voltage loss over distances.

How Voltage Drop Impacts 200 Amp Capacity

Voltage drop is the decrease in voltage occurring along the wire due to its resistance. The longer the wire runs, the more voltage loss becomes. To counteract the current drop, you must increase the wire conductor size.

The voltage at your circuit breaker should register at 120 volts. To check this, use a multimeter to measure the reading at the appliance or device farthest from the breaker.

Your voltage drop should not exceed 3%. So, for a 120-volt electrical circuit, your voltage drop should not fall below 117 volts. For a 240-volt electrical circuit, the voltage drop shouldn’t dip below 233 volts.

Underground 200 Amp Feeder Sizes for Long Distances

This 200 amp service wire size chart for copper and aluminum cables reflects the wire gauge and distance to account for voltage drop.

| Copper | Aluminum | Approximate Distance |

|---|---|---|

| 2/0 | 4/0 | 100 feet |

| 3/0 | 300 kcmil | 200 feet |

| 300 kcmil | 600 kcmil | 250 feet |

| 500 kcmil | 1000 kcmil | 300 feet |

| 1000 kcmil | 600 kcmil3 | 350 feet |

| 500 kcmil3 | 1000 kcmil3 | 400 feet |

For a distance of 100 feet, a 3/0 copper wire would be a suitable choice for a 200 amp service wire size.

You can use aluminum or copper for a 200 amp panel wire size. Aluminum has lower conductivity and heat resistance, increasing the wire gauge size. The aluminum wire would be your best bet for dealing with a longer distance, as it will save you money on wire costs.

What Size Service Wire For 200 Amps 200 Ft Away?

Consider voltage drop and current capacity to choose the correct wire size for a 200 amp service 200 ft away. To send power across a 200-foot distance, use a 3/0 or 4/0 copper wire or 250-350 kcmil3 aluminum wire.

What Size Service Wire For 200 Amps 300 Ft Away?

Consider what size wire you need for a 200 amp service 300 ft away or farther. To send power over 300 feet, use 600 kcmil3 aluminum wiring.

Installation Guidelines for 200 Amp Wiring

The best practice for running a new electric service is to consult the NEC for the correct wire sizes and breaker specifications. This ensures your services are up to code and can safely handle the amperage.

The specific type of electrical wire needed will depend on your electrical system. The cables running from the meter base to the main disconnect or panel are 3-wire. This system has two hot wires and one neutral wire. Electrical bonding connects the neutral and ground bars.

The wire connecting the main electrical panel to smaller panels inside your home has four wires. This comprises two hot wires, one neutral wire, and one ground wire. In subpanels, you don’t bond the neutral and ground bars.

When you put in a subpanel, think about how much power it needs and what size breakers to use. You want to make an electrical system that is safe and works well to power all your big appliances.

Direct Burial and Conduit Requirements

For a 200 amp service, the infrastructure that houses and protects the wiring is as crucial as the wiring itself. This section focuses on the requirements and considerations for direct burial cables and conduit systems, ensuring that the electrical installation is durable, safe, and compliant with regulations.

Direct Burial Cables

Direct burial cables are specifically designed to be buried underground without additional conduits for protection. They are robust, with insulation and sheathing materials that withstand moisture, chemicals, and natural soil acidity.

- Depth Requirements: Ensure that the burial depth meets the National Electrical Code (NEC) and local code requirements, typically ranging from 18 to 24 inches, depending on the cable type and whether it’s under a residential driveway or a public road.

- Protection Against Damage: In areas where physical damage is possible, consider additional protection such as concrete encasement or rigid metal conduit.

- Routing: Avoid areas that may be subject to future digging or construction. Mark the cable’s path above ground to prevent accidental damage.

Conduit Systems

Conduits protect wires from moisture, impact, and other environmental factors. They can be made of various materials, including PVC, metal, and flexible conduits, each suitable for different conditions and installation types.

- Minimum Size: For a 200 amp service, the conduit should be sized appropriately to accommodate the wires without overcrowding. A minimum size of 1.5 inches is often recommended, but this may vary based on the number of wires and the conduit material.

- Fill Capacity: Ensure that the conduit fill capacity adheres to NEC guidelines. Overcrowding can lead to overheating and damage to the wires.

What Size Conduit Do You Need with Insulation Considerations?

When installing electrical panels, you’ll need to attach the electrical feeder conduit to the knockouts provided. The pipe size depends on the fill space inside, which accounts for the insulation and the number of wires it contains. For a setup with three or more wires, the fill space should not exceed 40%.

Referring to Chapter 9, Table 5A of the 2017 National Electrical Code (NEC), a 4/0 Aluminum stranded conductor with insulation occupies 176.3mm2 of fill space. When you have four such conductors, the combined insulated area amounts to 705.2mm2.

For a 200 amp service, the 2017 NEC recommends a 2-inch Schedule 80 PVC conduit, which offers 742mm2 of usable insulated fill space.

A 2-inch conduit is sufficient for these insulated conductors, though you may consider upsizing to a 2.5-inch conduit to facilitate easier wire pulling and to accommodate any additional insulation thickness.

The pipe size that holds your wires affects how well and safely your electricity works. The NEC says how small it can be, but a bigger size could be better for future changes. Always ask an expert to find the best way to do this.

What Size Ground Wire Do You Need?

According to the 2020 NEC, the smallest ground wire size for a 200 amp service is 4 AWG bare copper conductors or 2 AWG aluminum.

Local governments use NEC guidelines for building construction, but not all codes are always followed. Local government agencies often need to catch up on electrical code adoptions. Talk to a licensed local electrician or your city’s building department for specific guidelines.

The NEC provides a guide, but local codes and professional advice should also be considered.

| Size of Main Panel | Copper Conductors | Aluminum or Copper-Clad Aluminum |

|---|---|---|

| 125 Amps | 8 AWG | 6 AWG |

| 150 Amps | 6 AWG | 4 AWG |

| 200 Amps | 4 AWG | 2 AWG |

What Size Ground Rod Do You Need?

The ground rod for a 200 amp service must be 5/8″ (0.625) in diameter. It should also be 8 to 10 feet long and have a clamp and the correct ground wire.

You should drive the ground rod 8 feet deep and cut it back close to the ground level. The wire and clamp must be fastened to the top of the ground rod.

New electrical code requirements say you need two ground rods in areas with high soil electrical resistance.

How Many Ground Rods Do You Need?

NEC code now requires you to use two ground rods in some instances. These grounding rods should be at least six feet apart if a ground rod doesn’t meet the NEC’s 25 OHMS rule.

Install a second grounding rod if the first ground rod for a system has a resistance of 25 ohms or more, as per the NEC. Many contractors don’t consider ground resistance.

Instead, they plan to drive two ground rods to meet the 250.56 standards, regardless of ground resistance. Nowadays, most areas require two ground rods for new installations and upgrades.

NEC Article 250.53(B) mandates grounding rods connected by a grounding wire at least 6 feet apart. Space them about 16 or 20 feet apart to get the best results. Use an 8-foot or 10-foot ground rod, which is farther than the minimum 6-foot spacing.

Check Local Electrical Codes & Permit Requirements

The United States has electrical codes based on the National Electrical Code (NEC). These codes may differ depending on where you are.

Hire a professional electrician to follow the codes when installing a 200 amp electric service. They know the local codes and pull necessary electrical permits.

Electricians base their suggestions for 200a service wire size on NEC guidelines. Your local building codes may differ. Many regulations use or change NEC codes for their 200a wire size requirements.

Before your utility company can connect power to your property, you must get a Certificate of Occupancy (CO). After a final inspection, the utility company can set the meter and turn on your electric service.

After passing inspection, the electrical work on your property gives the CO.

Upgrading from Lower Amp Ratings to 200 Amps

To install a 200 amp electrical service, you need a 200 amp service wire, conduit, meter base, and electric panel.

HomeAdvisor says the average cost for a complete 200 amp electric installation is $4,650. It can range from $1,900 to $7,250. These figures include the following:

- 200 Amp Service Panel: The average cost ranges from $750 to $2000, with a median cost of around $1,375.

- 200 Amp Meter Base: The average cost for this component ranges from $150 to $400, with a median cost of about $275.

- 200 Amp Service Wire: The average cost for this can range from $1,000 to $5,000, with a median cost of around $3,000.

Try an electrical panel cost calculator or get quotes from local electricians to estimate costs.

Get FREE estimates from licensed electricians in your area today. Whether you need to replace an outlet, hang a ceiling fan, a new electrical panel, or repair wiring, We Can Help!

Frequently Asked Questions

Let’s answer some of the most frequently asked questions below about 200 amp wire size.

Do I have to rewire to upgrade to 200 amps?

It may not be necessary to rewire your home when upgrading to a 200 amp service. To install the 200 amp service, you may require other upgrades. You can replace boxes, add grounding rods, and upgrade the meter base to improve the electrical system.

Is #2 and 2/0 wire the same?

No, the #2 and 2/0 wire gauges are not the same. The #2 wire is smaller in diameter and has less conductive capacity than the 2/0 wire.

Do I need to replace my existing electrical panel for a 200 amp service upgrade?

The electrical panel should have a rating of at least 200 amps. Look for any signs of damage, corrosion, or overcrowding of existing circuits. If unsure, consult a licensed electrician for an assessment.

Related reading: 80 Amp Wire Size: Breaker & Wiring Gauge Guide

Conclusion

There’s no one-size-fits-all answer. Each home and each installation has its unique requirements. Consulting with a knowledgeable electrician can help you navigate the pros and cons and make an informed decision.

You’ll need electrical permits for 200 amp service installation. To feed the new 200 amp wire, you might have to disconnect the power from the electrical utility service.

Always keep the NEC guidelines in mind, whether at the end of your DIY journey or just beginning to gather information. They are there to ensure every job, each wire, and every breaker is sized correctly for the safety and efficiency of your home’s electrical services.

Please refer to our Wire Size for 100 Amp Electric Service: Complete Guide for additional guidance.