Deck railings are meant to safeguard people from falling over raised decks, balconies, and stairs. And they consist of various materials whose costs differ.

For a basic deck railing, pressure treated lumber is the cheapest. Vinyl is best for low cost and low maintainance. What you pay for wood or vinyl deck railing may differ from what you pay for composite or metal deck railing. The former tend to be cheaper, while composite is an excellent mid-range option. On the other hand, metal deck railings are more expensive upfront but may be cheaper in the long term.

First, you need to understand what should influence your choice of deck railing before thinking of the costs. This article discusses the factors to consider when choosing a guard rail for your deck costs of wood, vinyl, composite or metal railing and the pros and cons of each material offers.

| Deck Railing Material | Material Cost (LF)* | Analysis |

|---|---|---|

| Wood | $40 to $50 | Price varies widely on species of wood and availability |

| Vinyl | $20 to $40 | Normally purchased in 6′ or 8′ pre-assembled panels, which saves on labor costs |

| Composite | $15 to $30 | Costs more than vinyl but is cheaper than some wood species (except pressure-treated lumber) |

| Aluminum | $40 to $70 | Aluminum resists corrosion, is low maintenance and you can easily customize its appearance, designs, and colors. |

| Steel | $30 to $80 | Stainless Steel is stronger than aluminum, making it resistant to scratches, dents, and dings. |

| Wrought Iron | $50 to $120 | More expensive than aluminum and steel. Highly suited for intricately designed railings. Wrought iron is also strong and durable, standing the test of time. |

Labor costs for most deck railing will cost $25 to $45 per linear foot. Exceptions will apply where intricate designs are used.

Factors To Consider When Choosing Deck Railing

When choosing a guard rail for your deck, it will help to consider the factors below.

1. Local Building Codes

It would be wise for you to pay close attention to the local building codes when choosing deck railing. That’s because they are meant to help property owners reduce accident rates.

These building codes may vary depending on location, the building type, and the exact position of the railing. But once you learn what they are, you can determine which material best suits your needs.

For example, the general rule of thumb is that any deck 30 inches or more away from a surrounding surface must have railings. The handrails on the deck stairs must be anywhere from 34 to 38 inches in height. On the other hand, balusters should be less than four inches apart. That’s to ensure children find it harder to jam their heads in between the spaces.

Building codes also dictate that deck railings must resist specified loads, have the necessary shape and measurements to improve grip, and not present obstacles that injure their users.

Since different regions may have unique additional building codes, it is best to consider them before choosing your materials.

2. Cost-Effectiveness

Your budget will largely influence your choice of deck railing.

A typical guardrail for your deck will cost you anywhere from $15 to $600 per foot for the materials alone. Those made of vinyl will probably be the cheapest. And most metal railings will be costlier. Labor will cost you an additional $30 per foot on average. In addition, you need to consider the construction permits.

It is up to you to decide how much you are willing to spend. But remember, you need to have enough money on hand to complete the entire guard rail. You cannot leave it incomplete because that would be dangerous.

3. Durability

How long do you intend to have your deck railings without replacing them?

Since deck guard rails are exposed to the elements, they tend to take a beating. And that influences the durability. Most of them can last a decade or two. But some can last much longer than that. Generally, sturdy materials that resist rot, corrosion, or breakages better will likely serve you for a very long time to come.

4. Maintenance Requirements

Sometimes it takes a lot of effort on your part to make your deck railing continue to look good and function as it should. But high maintenance materials can be a nuisance because few people want to spend so much time dealing with them.

For that reason, you need to consider the maintenance requirements of every type of deck railing. You can do that by paying attention to its durability, how easy it is to clean, whether it requires retouches often over the years, and whether you would need to repair the guard rail constantly. Typically, composite and vinyl railings tend to be low maintenance.

5. Design Aesthetics

How your deck railing looks is a matter of concern. In this case, appearance refers to the colors, shapes, texture, style, and feel.

Also, you need to consider the guard rail’s design and your property’s existing theme. It should look as if it were part of the original design, even if it is not. Otherwise, it will end up looking like an after-thought and may spoil the look of the home you were going for.

Which Deck Railing Costs Less: Wood, Vinyl, Composite, Or Metal?

Once you consider other relevant factors concerning the choice of deck railing material, you can then think of the cost. Below is a cost breakdown of some of the more common guard rail materials.

1. Wood Deck Railing

Wood deck railing is one of the most popular choices among homeowners today. And it has been in use for years.

In terms of cost, wood deck railing is one of the popular products around. Depending on whether you use pressure-treated lumber, ipe, mahogany, cedar, or redwood, it will cost you anywhere from $2 to $35 per square foot in materials. Alternatively, you will need to spend an average of $40 to $50 per linear foot.

Depending on the kind of wood used, the railing can be pretty resistant to the elements and, thus, durable. For example, ipe is a highly dense wood that is naturally resistant to rot and insects. In terms of cost per linear foot, it will cost you $33 to $45.

In addition, they have a fire rating similar to that of concrete and steel! And it can last for 50 years without any replacement. However, it needs some maintenance involving oil treatment. But such maintenance can extend its life by an additional 25 years.

Mahogany, redwood, and cedar are other excellent wood alternatives you can use for your deck guard rail. They may not be cheap, but they have high resistance to moisture and rot, insect attacks, mold, and general decay. Expect to get at least 20 years from your cedar, mahogany, or redwood deck railings.

But you don’t have to spend that much if you have a limited budget. You can always opt for pressure-treated lumber as your deck railing material of choice. It will cost you $22 to $30 per linear foot. And it can last as long as other premium woods.

Generally, wood deck railings (except those made from ipe) are not as durable as those made from other materials. And they can bend over time due to exposure to the elements. These will need to be a part of your routine wood deck maintenance.

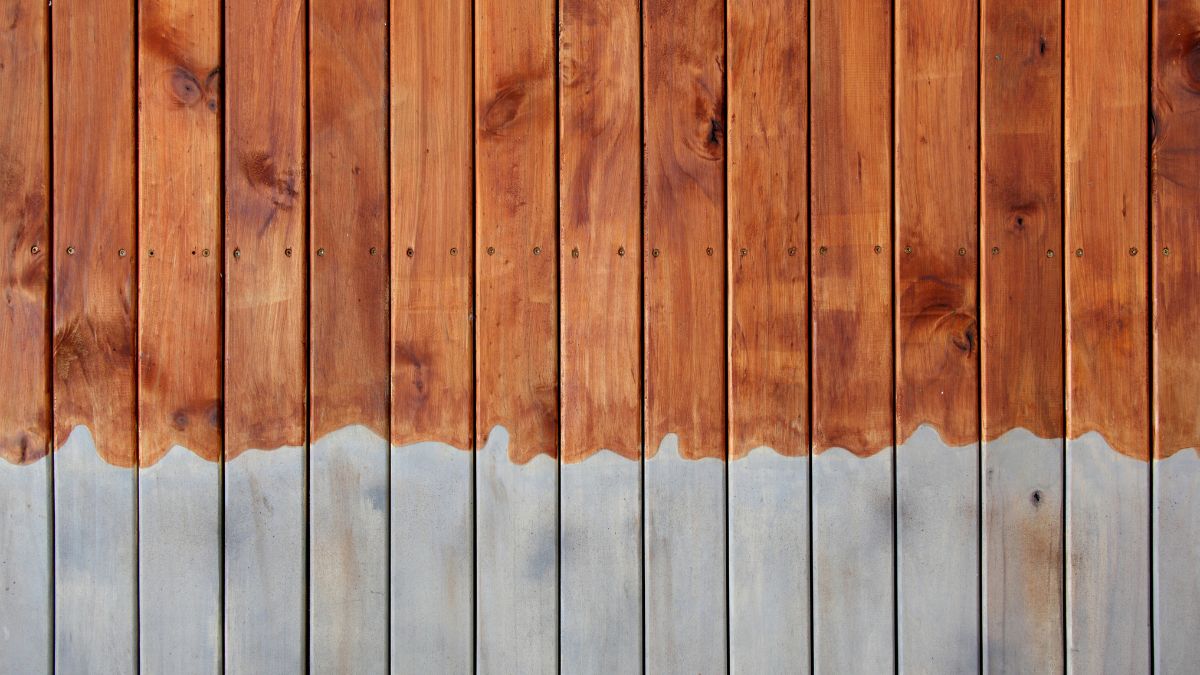

Also, they are not very eco-friendly because they involve cutting trees or using toxic chemicals to treat the lumber. In addition, they have relatively high maintenance requirements, such as washing, oil treatments, and painting.

However, wood provides a natural and stylish look. The nature of wood is such that it is easy to customize it using various paints, stains, and sculptural designs. Furthermore, it is cost-effective and provides the natural wood feel that so many people love.

2. Vinyl Deck Railing

Vinyl (Polyvinyl chloride) is a synthetic plastic polymer that is popularly used in many products. A deck railing consisting of the material tends to take its characteristics.

In terms of cost, vinyl deck railings are pretty affordable. It will cost you an average of $9 to $16 per square foot or $20 to $40 per linear foot. But how does it measure up?

Well, vinyl deck railing is pretty cheap, which means you can install it even on a limited budget. In addition, it is non-biodegradable, which makes it highly durable. It’s also worth noting that vinyl is scratch-resistant, splinter-free, insect-resistant, and very easy to assemble. Furthermore, it is low maintenance and only requires a little washing once in a while.

That said it vinyl deck railings have their fair share of weaknesses. For starters, due to prolonged exposure to sunlight, vinyl tends to crack and fade. That ends up compromising its beauty. Also, it is structurally weaker than other materials such as wood and metal. And sometimes, it can be unnaturally looking, making it a terrible choice if you want a natural feel to your deck.

Also, it is limited in terms of colors. You cannot paint it and thus, must live with your initial color choices for as long as the deck railing stands. That could prove quite challenging if you makeover your home and change the overall design theme.

3. Composite Deck Railing

If you intend to use composite as the material of choice for your deck and railings, expect to pay $8 to $16 per square foot. These costs translate to $15 to $30 per linear foot of materials.

And that is cheaper than most premium wood guard rails but slightly more than or at par with the lower-cost vinyl and pressure-treated lumber deck railings options. For this reason, it is an excellent mid-range guard rail option if you have some leeway in your budget.

A typical composite decking material usually consists of both wood and plastic components mixed in various ratios. Many of these components come from recycled materials, thus reducing the impact of waste on the environment. As a result, composite deck railings are an excellent choice for those who desire an eco-friendly option to safeguard their stairs, decks, and balconies.

Due to the inclusion of wood components, composite deck railings can give a natural wood appearance, which is essential for those who want to keep a natural design theme. And unlike vinyl guard rails, it comes in many colors.

They are also durable and tend to be associated with long-term warranties of as many as 25 years. Therefore, you don’t have to worry about insect attacks or rot. In addition, composite guard rails are low maintenance, thus do not need a lot of painting or staining.

That said, a composite deck railing comes with its share of cons. For starters, it is not the cheapest deck railing material available. And while it can be customizable, you may need to spend more on upgrade features to make that happen. In addition, it is not as structurally strong as metal and wood railings and, thus, may require more support.

Also, composite deck railings tend to become softer due to prolonged sun exposure. That, in turn, causes them to bend and sag. So, it would help if you were very careful when engaging in activities, such as grilling. But the material does not splinter or crack.

It’s also worth noting, though, that prolonged sun exposure will discolor your composite deck railing over time, which affects its overall aesthetic value. And like vinyl railings, you cannot paint composites over. The color you choose is what you get stuck with.

The maintenance requirement of composite deck railings varies. Depending on the brand, some may only need regular cleaning. However, other composite materials may require special cleaning agents. And should anyone damage your railing, your repair options are limited. You cannot fix it or sand it down like wood. You likely have to replace the entire damaged part.

4. Metal Deck Railing

Multiple types of metal can be used to make your metal deck railing. These include aluminum, steel, stainless steel, and wrought iron. The nature of these materials and demand tends to affect their average prices.

For example, if you want aluminum deck railings, expect to pay $40 to $70 per linear foot. Stainless steel will cost $30 to $80 per linear foot, while wrought iron will cost $50 to $120 per linear foot. So, it’s safe to say that generally, metal is the most expensive guard rail material compared to wood, vinyl, and composite. So, what makes them that costly?

- Aluminum

Aluminum railings tend to be strong but also lightweight and very flexible. That makes them an excellent option for DIY homeowners who can carry them around. Also, aluminum does not rot or get attacked by insects. It is recyclable too, which makes it an eco-friendly option for homeowners concerned about the environment.

Furthermore, aluminum tends to be somewhat resistant to corrosion. And it is usually coated to improve its ability to resist corrosion even more. In addition, aluminum is low maintenance and doesn’t require painting, staining, or other treatments to preserve its naturally stylish appearance. Also, you can easily customize it to change its appearance, designs, and colors.

However, the most significant drawbacks concerning aluminum are the relatively high costs and vulnerability to scratches.

- Stainless Steel

Stainless Steel tends to be stronger than aluminum. Therefore, it is more resistant to scratches, dents, and dings. The strength also makes it a great choice if you want railings that bear heavy loads. Also, it is stylish and, thus, aesthetically pleasing. In addition, stainless steel railings have a high fire and heat resistance, thus enabling them to withstand prolonged exposure to sunlight with minimal damage.

In terms of maintenance, stainless steel is easy to clean. And it is also recyclable, thus making it an eco-friendly option. Moreover, it is easy to fabricate, enabling you to create intricate designs based on your desires.

The biggest drawback of stainless steel railings lies in their high prices. It also shows smudges easily too.

- Wrought Iron

The cost of a wrought iron railing could shock you if you had no idea of what it costs. But good reasons exist for the material’s expensive price tags. First, wrought iron is highly suited for forging, making it one of the best choices for intricately designed railings. Wrought iron is also strong and durable. In addition, it is aesthetically pleasing and ages well.

However, the material is not only expensive, but it is also high maintenance. You may need to clean and repaint it regularly. If you don’t do that, it can rust over time. And that will reduce its beauty.

Final Thoughts

If money is the only consideration when choosing deck railings, then pressure-treated lumber or vinyl deck railing is the best option for your needs. However, if you are willing to consider other factors, your choices will vary depending on your priorities. Wrought iron can produce very beautifully designed railings. But you should have a huge budget for that.

On the other hand, aluminum, stainless steel, and composites are excellent choices for those worried about their impact on the environment. However, composites are more affordable. In the end, your decision depends on your current budget and what gives you the best long-term value for your money. So, choose wisely.

References

U.S. Building Codes for Deck Railing