Deck beams align on top of posts as single or multiple boards fastened together to provide the base for the deck joists, which provides the base for the decking. Therefore, the size of deck beams that you need depends on the deck’s size and spacing in between beams.

The International Residential Code (IRC) determines the size of your deck beams related to the deck beam span. The deck beam span is the distance between the center of each post supporting the deck beam. The IRC covers the maximum deck beam span for a wide array of deck beam sizes depending on the wood species and the size of the dimensional lumber making up the deck beam.

In the past, solid squired beams such as 4×4 and 6×6 were used for beams in deck building, but not anymore. Now, deck beams with a thickness of 2” are acceptable, giving you the option to double up or triple up the boards to create beams at the job site from 2×6, 2×8, 2×10, or 2×12 lumber depending on your construction plan.

What Size Beam do You Need for Your Deck?

The question of what size deck beams you need correlates with the spacing of both beams and joists.

The deck beams’ size and spacing are also the sections of the decks’ structural foundation that the international residential and building code strictly requires homeowners and builders to adhere to.

Calculating and finding the right size of beam to use on your deck depend on different factors;

- The size of the deck itself

- The species and quality of the timber that is being used

- The number of joists that will sit atop deck beams

How Big of a Deck Beam do You Need?

Deck beams span measures the distance between the center of each post supporting the beam. While the deck beams can be made from 2×6 lumber, we recommend using 2×8 lumber or larger for deck beams to help stabilize and distribute decking weight accordingly.

Deck Beam Span Lengths for Southern Pine

| Joist Span | Joist Span | Joist Span | |

|---|---|---|---|

| Lumber Size | 8′ | 12′ | 16′ |

| 2 – 2×8 | 7’7″ | 6’2″ | 5’4″ |

| 2 – 2×10 | 9′ | 7’4″ | 6’4″ |

| 2 – 2×12 | 10’7″ | 8’7″ | 7’6″ |

| 3 – 2×8 | 9’6″ | 7’9″ | 6’8″ |

| 3 – 2×10 | 11’3″ | 9’2″ | 7’11” |

| 3 – 2×12 | 13’3″ | 10’9″ | 9’4″ |

Deck Beam Span Lengths for Other Wood Species

| Joist Span | Joist Span | Joist Span | |

|---|---|---|---|

| Lumber Size | 8′ | 12′ | 16′ |

| 3×8 or 2 – 2×8 | 5’11” | 4’10” | 4’1″ |

| 3×10 or 2 – 2×10 | 7’3″ | 5’11” | 5’1″ |

| 3×12 or 2 – 2×12 | 8’5″ | 6’10” | 5’11” |

| 3 – 2×8 | 8’6″ | 6’11” | 6′ |

| 3 – 2×10 | 10’5″ | 8’6″ | 7’4″ |

| 3 – 2×12 | 12’1″ | 9’10” | 8’6″ |

For example, a single 2×10 beam will require a post between 7′ and 4′ depending on the deck joist span.

Another example is that of 2×6 beams, which can support joists and decking loads at intervals of 2’8″ and 4’11” depending on joist span.

The problem now is that too many posts will be required, so the best thing to do is to double up or triple the deck beams to double the strength and allow for wider spacing of posts and beams.

Now, two pieces of 2×6 fastened together will be comfortable enough to serve and support 6 feet of the joists and the decking.

Same as 2×8, 2×10, and 2×12 beams.

- 2 pieces of 2×8 will travel 8 feet before another set of deck beams takes over. 3 pieces of 2×8 planks will travel 12 feet before transferring the weight of joists and decking to the neck beam or consortium of deck beams.

- 2 pieces of 2×10 deck beams will serve 10 feet in distance, 3 pieces 15 feet, and 4 pieces 20 feet.

Deck beam size calculation may seem or sound easier to do until it is not. If you sense that getting it right will be hard to achieve, then it is best to call up a season deck constructor to help you out.

This is a common rule of thumb to erect a post half the distance of the beam length, but this is not accurate.

You should follow deck beam spans in IRC Table R507.5.

How is Timber Species Related to Size of Deck Beam?

Hardwoods are not mostly recommended for the construction of housing structures as they buckle under the pressure of weather and might crack along grains as well as a curve or bend when they encounter a heavy load.

Primarily, hardwoods are used in making furniture such as seats, tables, beds, among others. That is because they are heavy and will give the piece of furniture the feeling of strength and mobility.

On the other hand, construction requires lightweight and strong wood and does not split or crack because, unlike wooden furniture whose imperfections are sealed and furnished with sealants and paint, timber for the building has none.

Indigenous trees and an assortment of softwoods, on the other hand, are perfect for construction.

These include:

- Southern Pine

- Douglas Fir-larch

- Hem-fir

- Spruce-pine-fir

- Redwood

- Western Cedars

- Ponderosa Pine

- Red Pine

Deck Beam Size Versus Joist Spacing

The size of the deck beam required and the spacing joists will be accorded as the thickness of beams is dependent on the amount of load it will bear immediately or afterward.

Beam size and joist spacing work hand in hand to deliver a sensible and practical result.

Deck beams bear all of the weight, including the joists, decking, and even the roof, if there is one. The strength and stability of the deck beams are essential to the deck’s safety, both in the long and short term.

Are Beams Necessary in the Construction of a Deck?

Whether it is in the roofing of a deck or the construction of the raised wooden platform, joists would have nothing to sit or get support from, and the attempt at constructing something sensible would be futile.

Deck beams and posts, ledgers, and joists all form the foundation of the deck structure, which is critical for the strength of the entire system and the safety of the deck for the people who use it.

You could as well say that deck beams are the soul of the deck as they determine how long the deck will last.

The deck beam and the ledger are installed parallel to each other but join perpendicularly through the installation of joists. You could say that the beam and the ledger work and depend on each other on different levels.

In the construction of wooden platforms suspended from the ground, these beams are also referred to as girders or girders, depending on the number of fastened together using bolts to create one solid block.

Using a single square solid beam of 4, 6, 8, or even 10 would be easy and save plenty of time and money; however, fastening or fashioning double or multiple beam plants together forms a more robust and long-lasting alternative.

Solid squared beams have several disadvantages;

- They are too heavy for a job that requires light but strong

- Because of their weight, they become hard to handle

- For the above reason, successfully installing them becomes a challenging task and takes much time.

- Solid squared beams, unlike other beams, buckle under the pressure of weather elements as they are exposed. When they start to crack, the safety and strength of the deck are compromised.

No one is restricted on the number of beams to fasten together to form a single unit as long as they are adequate to take in the weight of the joists and decking and are consequently correctly installed for the greater good.

In some instances, the use of beams as many as 4 or 5 have been witnessed.

So how do you determine the size of beams for your deck? Looking at the importance of beams to a deck enables you to calculate the dimensions of beams about spacing accurately.

As mentioned above, deck beams are vital for the deck’s structural integrity and act as a sort of centerpiece for the whole structure.

How to Choose the Right Lumber Type

Deciding on the lumber size has a lot to do with choosing the right type of lumber for your deck. Lumber types can fall into one of the following categories.

- Pressure Treated Lumber

- Naturally Resistant Species

Pressure Treated Lumber

Most often, this type of lumber can be pine or fir. Primarily, pressure-treated lumber is heat-resistant. It is treated with chemicals. Such can be perfect for warm countries.

One of the highlights of this type of lumber is that it’s inexpensive. However, it’s wise to be careful when choosing to ensure that the lumber you get is free of loose knots.

Naturally Resistant Species

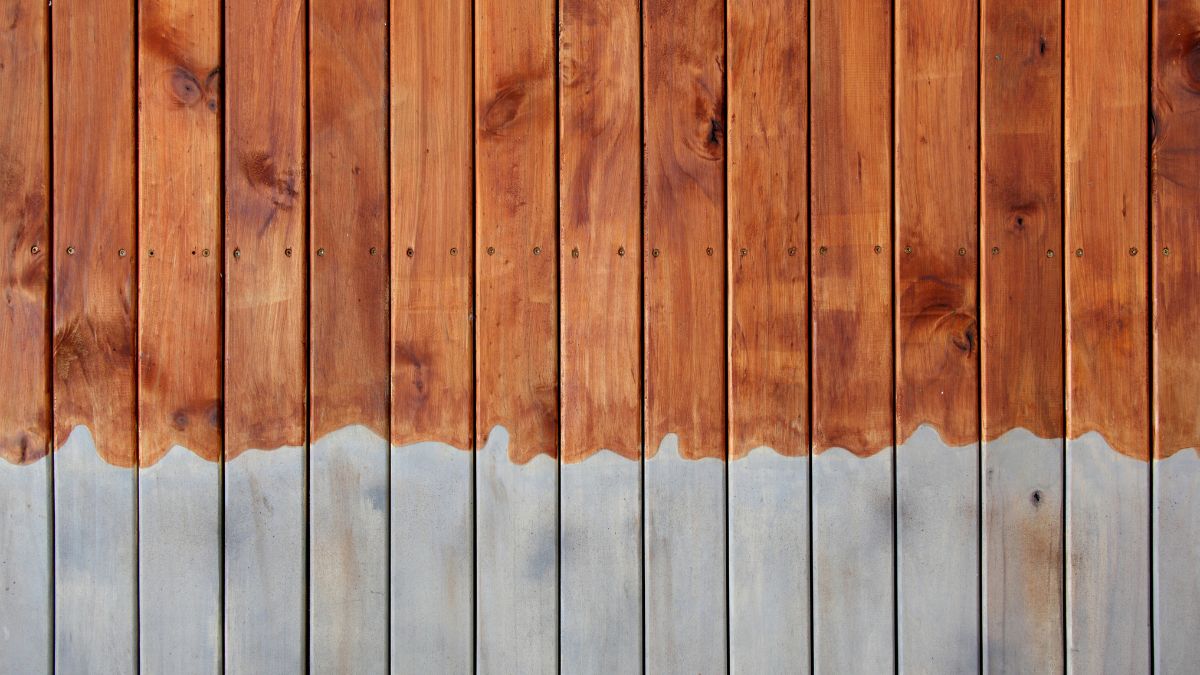

Often, this type of lumber is redwood, cypress, and cedar. The highlight of this type of lumber is that it’s resistant to rotting and insects.

To retain the natural beauty of the tree source, you can seal or stain the wood before using it to build your deck.

If you have the budget, Meranti, Cambara, or IPE are great choices. They are all very durable and are great as deck beams.

Can You use 2×6 Lumber as a Deck Beam?

The thickness of the deck beam directly equates to how much weight it can carry before straining and eventually breaking. The thinner the beam, the less strength it has and the less ability it has to bear the deck’s weight.

Consequently, the bigger or greater the thickness of the decking beam, the better.

2×6 deck beams are smaller than the job at hand, but they can still be used not as single entities but as a composite of up to 3 pieces of 2×6 to form a 6×6 beam block.

This begs the question, can the thickness of deck beams be the same as the thickness of joists?

This is a valid question, given that most structural joists use 2×6, 2×8, and 2×10 lumber over 2×4 lumber and anything smaller.

The rule of thumb is the more prominent your deck, the larger the joists you will need as the deck will be heavier. Similarly, the bigger the posts, the bigger the beams should carry and distribute the decking weight accordingly.

Can You use 2×8 Lumber as a Deck Beam?

The ultimate or the perfect size deck beam to always use is a 2×10 and a 2×12, But nature teaches us how to effectively and ideally use what is at our disposal.

So in the true sense, 2×8 beams can be used as doubles or triples and are much better and yielding than the 2×6 beams.

In this reference, 2×8 beams should span a distance of 4, 8, or 12 feet depending on the number of beams fastened together. The use of the 2×8 beams also depends on what type of joist on beam joining you will go for. There are two;

- The drop beams allow the beam to settle below the outstretched joists

- And the flush beam where the posts and the beam meet perpendicularly in a flushing manner.

The drop beam type of construction is the favorite between the two and the strongest for that matter as it can distribute any amount of decking weight across the pillars of the foundation and can accommodate bigger-sized joists without stress.

Flush beams structural designs, on the other hand, are delicate as joists are fastened onto the inner side of the decking beam using metal fasteners.

This type of design may be more practical on smaller decks that also use smaller beams in terms of thickness, such as 2×6 and 2×8, as the weight of the joists and the decking is dependent on the metal fasteners for the long term.

Final Thoughts

The size of the deck beam used is imperative to the deck’s strength, and the style used to join the joists to the beams also determines how strong the overall deck will be.

But other factors such as the grading of wood come into play.

Different grades have different strengths, and getting the right one ensures that the deck is uniform in terms of strength and durability. It is necessary to employ the use of the same graded timber across the foundation.

Sources

- How Far Can a Deck Beam Span?

- Deck Framing: How to Determine Deck Framing Lumber Sizes

- Ground Rules for Grade-Level Decks