You won’t weaken if you follow these guidelines when drilling holes through wood framing members.

Floor joists are the structural foundation of your home. Notching or drilling holes through them can compromise their integrity and lead to significant damage, costing you time and money. In this blog post, we’ll show you how to safely identify floor joists and avoid damaging them when making repairs or installing fixtures in your home. Stay safe and informed!

Dimensional Lumber

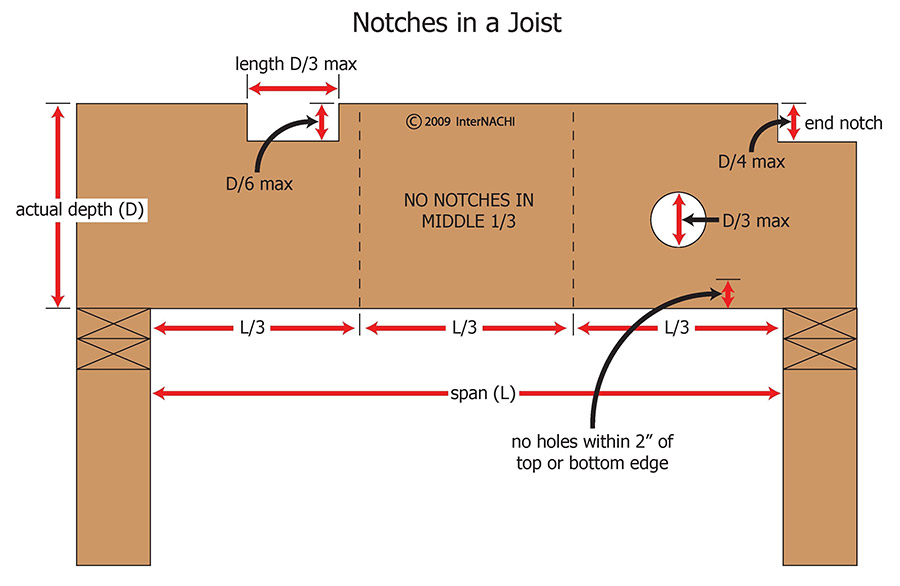

Don’t drill holes with a diameter larger than one-third the depth (1/3) of the joists. Stay 2 inches away from the top and the bottom edge of the joist.

Depending on whether you’re installing an electric cable or running pipes through wood joists, where and how to install them matters.

If you use dimensional lumber for floor joists, keep the holes in the middle if possible, spaced no closer than two inches from the top and bottom of the joist. The hole must not exceed 1/3 the size of the floor joist size.

For example, a 2×12 floor joist has a nominal size of 1-1/2 x 11-1/4 inches in size. The maximum drilled hole should not exceed 3-3/4 inches which are large enough for most plumbing pipes and electrical chases. See diagram below.

Never notch or drill holes in the middle third of the joist.

| Joist Size | Nominal Thickness | Notch Maximum Size | Drill Hole Maximum Size |

|---|---|---|---|

| 2×6 | 1-1/2″ x 5-1/2″ | 9/10″ – 1-4/5″ | 1-4/5″ |

| 2×8 | 1-1/2″ x 7-1/4″ | 1-1/5″ – 2-2/5″ | 2-2/5″ |

| 2×10 | 1-1/2″ x 9-1/4″ | 1-1/2″ – 3″ | 3″ |

| 2×12 | 1-1/2″ x 11-1/4″ | 1-4/5″ – 3-3/4″ | 3-3/4″ |

However, if you are using engineered floor joists, you’ll need to follow a different set of guidelines. Let’s discuss them below:

Engineered I-Joists

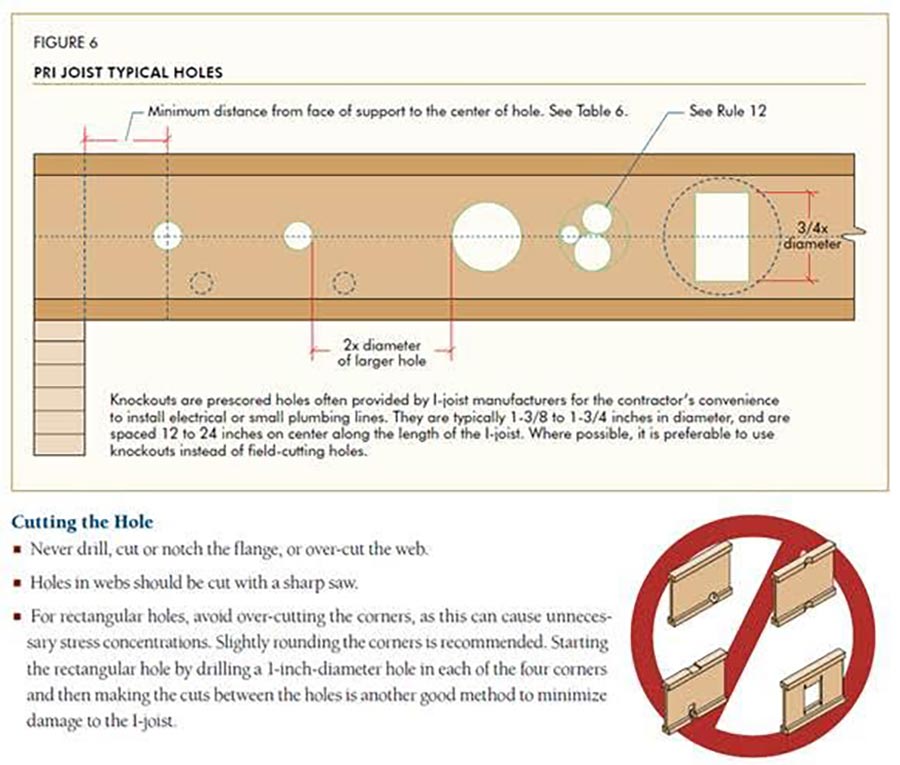

You can drill holes in engineered I-joists using different hole saws. You may need to drill holes near the edges of the I-joist for electrical wiring. Never cut the upper or lower flange or over-cut the web. It would be best to drill holes near the center of the joist for larger plumbing pipes.

In engineered I-joists, you can drill holes up to 1-1/2 inch diameter almost anywhere in the web area between the flanges, provided they are at least 6 inches from the end of the I-Joist or load-bearing wall.

You can drill holes up to 4 inches in diameter in the middle of the I-joist. Just stay away from the end of the I-Joist and load-bearing wall.

All spacing between holes needs to be at least twice the distance of the largest hole. For example, if the largest hole is 4″, the holes need to be spaced at least 8 inches apart.

Engineered I-joist have prefabricated holes that are 1-3/8 to 1-3/4 inches in diameter spaced 12 to 24 inches apart along the length of the I-joist. Where possible, you should use these knockouts rather than drilling new holes.

Notch Dimensions Are Different then Drilling

The situation is different when it comes to notches instead of drilling holes. Notches should be no larger than one-sixth (1/6) the height of the floor joist.

A notch in a joist prevents it from distributing weight effectively. As discussed in Load-Bearing & Non-Load Bearing Walls: What’s the Difference? (Explained), the floor joists are critical in distributing weight above to the foundation.

A notch compromises the floor joist and disrupts the weight distribution to the foundation. The result can be a sagging floor.

The beam easily withstands the transferred weight in a correctly notched floor joist. However, if the notch is too large, it can expand and eventually split or break.

Notches should always be no more than one-sixth of the joist. Never notch a floor joist at the middle third of the joist or greater than one-sixth of the joist height.

End notches should be no greater than one-fourth (1/4) of the joist height.

The length of a notch should extend no farther than one-third the height of the height.

For example, for a 2×12 floor joist, the notch should be no greater than 2 inches deep and 4 inches in length.

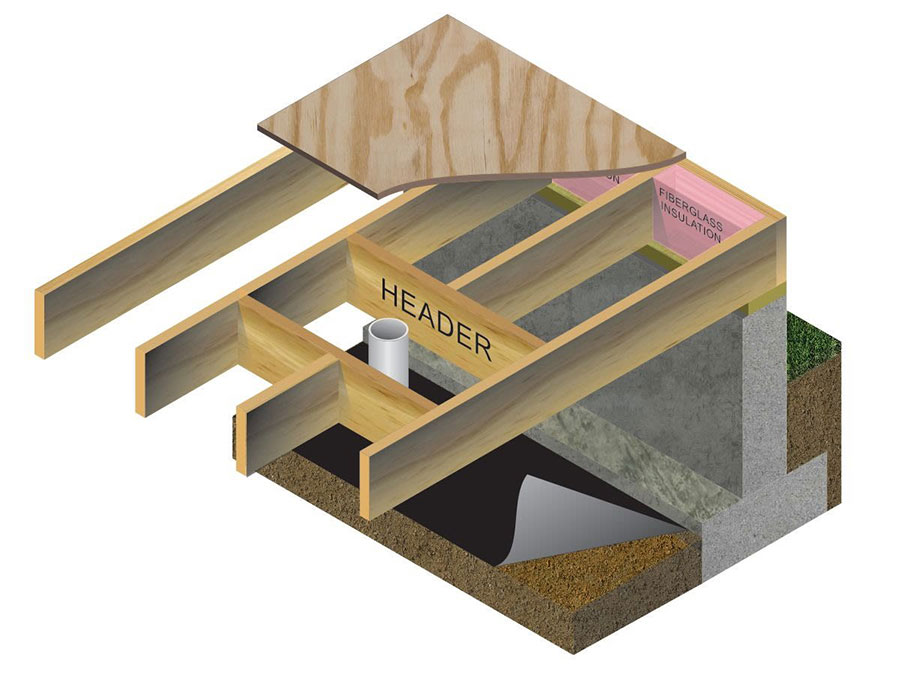

If you need to notch a floor joist for plumbing in a bathroom or kitchen, it’s best to cut out the floor joist needed. Then brace the cut floor joist on each side with a header secured with joist hangers on the adjacent floor joist. See an example below.

Do You Actually Need to Drill a Hole?

Before drilling a floor joist, ask yourself if drilling holes in the joist is necessary. There are better ways to install these things. You should inspect the joists before drilling and only drill if no other option is available.

People commonly drill joists for installing:

- Water supply lines

- Waste piping

- Electrical wiring

- Internet and phone cabling

- Gas piping

Technically, every time you drill holes in a joist, you weaken the joist’s structural integrity, even if the holes are within IRC guidelines. Let’s be honest; drilling a few holes in one joist won’t result in a cataphoric structural failure. It just doesn’t work like that.

However, it’s entirely feasible that you can weaken a joist enough to cause it to eventually split or even break, causing your floor to sag in that isolated area. We discourage drilling unless no other choice exists. Here are some alternatives.

Use Staples or Clips to Secure Wires or Pipes

Staples are not allowed in finished areas or areas that you could finish. You should check with your local city or county for local codes. Most local codes allow the use of plastic wire and plumbing clips.

These clips are held in place with small nails instead of staples and are easy to install. The wire clips can hold electrical wiring or another cabling. The plumbing clips are a circular design open on one side and can hold either water or gas piping.

If you are running cables or pipes through the attic or crawl space and need to secure them in place, using staples or clips is a better option than drilling a bunch of holes in the joists.

Pass Over Obstructions

It’s better to pass over ductwork or other obstructions if possible to avoid drilling holes. You can use staples or clips to secure the wiring or pipes to the joists.

Use Existing Holes Where Possible

If a hole is already present in the joist, you can go ahead and use it. Just pass your wire or pipe through the existing hole. If you need to widen the hole, you can follow the parameters above.

Avoid combining feed wiring through existing holes in combination with:

- Hot water pipes

- Metal ducting

- Metal joist brackets

If you need to drill through the floor joist, follow the guidelines above.