When flooring is installed in a home, knowing the floor structure is essential. The floor joists support the subfloor and underlayment, providing support for the flooring. Today, contractors use different floor structures in homes – but how do you know what type your home has without tearing up all of your floorings?

Dimensional lumber is used for floor joists, for example, 2x6s, 2x8s, or 2x10s. Engineered wood beams and floor trusses are specialty products built to be straight and strong and span 30 feet. Most contractors use engineered wood beams and floor trusses in new construction homes to save on construction material costs.

Read on to find out about these three components, so you’ll be able to identify them when they show up at or near your house!

What is Subfloor?

The subfloor is the material layer that sits directly on top of the floor joists, engineered wood beams, or floor trusses. The subfloor provides a flat surface for installing the finished flooring like carpet, laminate, or tile.

The most common type of subflooring is plywood, but you can also find panels made from other materials such as fiberboard and cement-based composites.

Oriented Strand Board (OSB) quickly overtakes plywood as the most common subfloor material because it is strong yet costs less than plywood.

If you’re looking to replace your flooring, it’s essential to know the condition of your subfloor. If the subfloor is damaged or rotten, it will need to replace it before installing new flooring. You can also add a thin layer of plywood called Luan over an existing subfloor if you need a smooth surface for your finished flooring or if you’re looking for an inexpensive option.

The subfloor is usually installed right after the floor joists are in place. Once it’s down, underlayment can be added over the top of it so that your flooring will have a smooth surface to rest. You may also want to put a floor protector on top of the subfloor to help keep it in good condition.

If you’re looking for a way to improve your home’s insulation, adding a layer of subflooring is an excellent option. It will also help to reduce noise from footsteps and other sound transmissions.

What are Floor Joists?

The floor joists are what provide support for the subfloor and underlayment. Floor joists are dimensional lumber such as 2x6s, 2x8s, or 2x10s which span up to 16 feet in length. These joists run perpendicular to the floor itself, so they lie underneath where you walk or stand in your home – which is why they need to be strong enough to hold up against weight!

The floor joists span between the floor beams of your home – but sometimes, you may find floor joists outside of your floor beams. These floor joists will require more support, so they may be connected to the top plates with metal hangers or straps to keep them secure and stable.

The floor joist provides a strong foundation for all other components – but it can also move if there is too much pressure on it from the flooring materials. If you find that your floor joist is moving, you can add metal hangers to keep them in place or install a plywood subfloor over top of the existing floor joists for added support and insulation.

Years ago, floor joists were cut from old-growth trees like Fir or Spruce. They were very insect resistant, strong, and straight. Now, builders are turning from dimensional lumber to engineered products. Newer dimensional lumber comes from fast-growing trees like softer wood like pine, which often causes dimensional lumber to twist or bow easily.

What is Engineered Wood Beams?

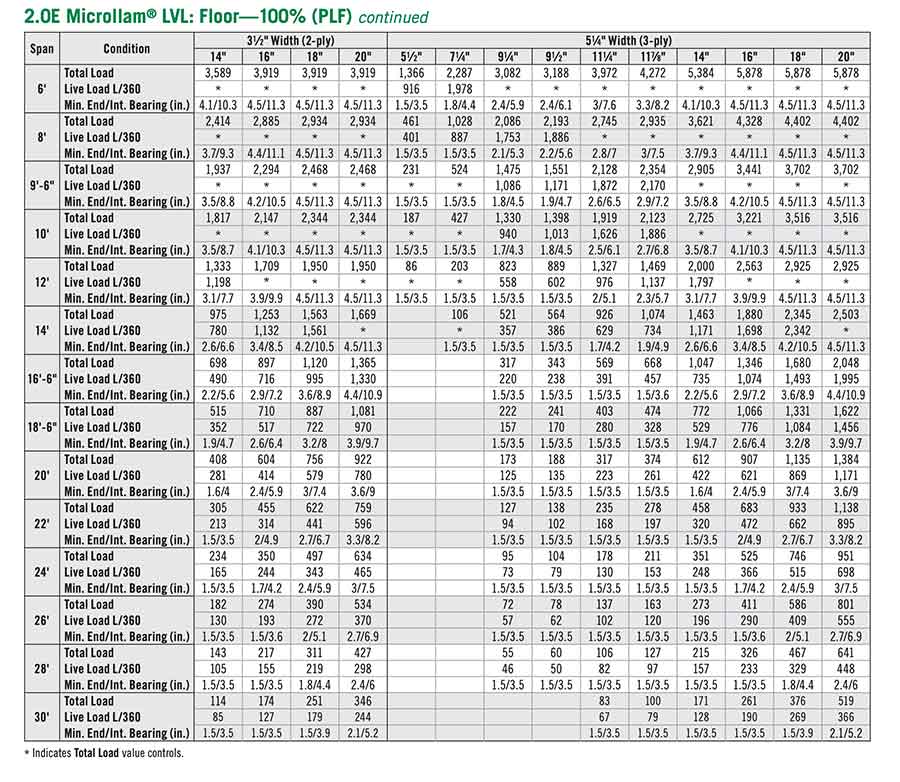

Engineered wood beams are a type of beam that consists of multiple layers of wood veneers. The veneers are glued together in opposite directions, which gives the beam added strength and stability.

You can use engineered beams for flooring, roofing, and many other applications where an intense beam is needed.

Engineered wood beams can span 60 feet in length, which is much further than dimensional lumber. Engineered wood beams work well with engineered I-Joists in building floor systems.

Engineered wood beams are often used in place of traditional lumber because they’re more resistant to moisture and warping. They also come in various sizes and shapes, making them versatile for many different applications.

What is Engineered I-Joists?

The I-joist is a strong yet lightweight “I” shaped engineered wood structural component that meets stringent performance requirements. The top and bottom flanges resist bending together with the webs, which provide excellent shear resistance.

The flange is made of laminated veneer lumber (LVL) or solid sawn wood, and the web consists of plywood or OSB. The sturdy combination of structural features makes this versatile, low-cost framing component easy to install in residential and light commercial structures.

I-joists can span greater distances than traditional lumber and floor joists, making them ideal for building floor systems. I-joist floor systems distribute loads evenly, minimizing the risk of damage to your home or building.

Engineered I-Joist Spans

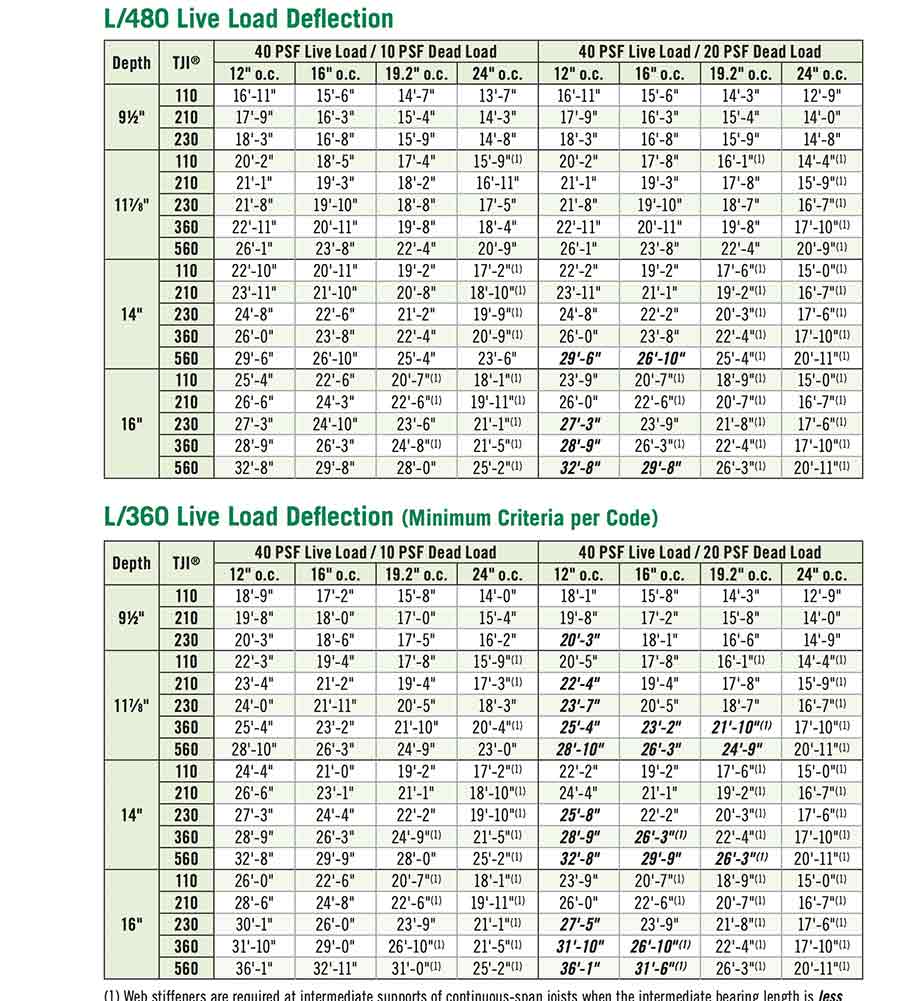

You can calculate the I-joist span using the most common variables, such as 16 inches between joists. You can create floor plans and check the spacing between I-joists, taking all factors into account.

A floor plan is a blueprint that serves as an outline for building projects like homes or office buildings, while floor joist spacing dictates how much weight the flooring system will hold. I-joists vary in size depending on the project.

The length of the I-joist refers to the span. The L/480 table, which has a 40 pound per square foot live load and a 20 pound per square foot dead load with a depth of 11 7/8 inches, will provide spans based on joint weight.

The lightest joist on the L/480 table will have a maximum span of 16 feet, 8 inches. The heaviest joist and the criteria mentioned above will reach a maximum span of 29 feet, 8 inches.

What are Floor Trusses?

Floor trusses are a type of floor system made from metal or wood. They are lightweight and easy to install, making them a popular choice for many homeowners. Floor trusses come in various sizes and shapes, so you can find one that is perfect for your specific needs.

Floor trusses are often used in place of traditional floor joists because they’re more resistant to moisture and warping. They also come in various sizes and shapes, making them versatile for many different applications.

There is often a misconception that floor trusses and floor joists are interchangeable – but this is not the case. You can install floor trusses in place of floor joists, but they cannot work as replacements for other components such as beams.

Floor trusses are common in floor systems because they have gaps that allow plumbing and ductwork to easily pass through the truss without cutting or damaging the truss.

Floor Truss Spans

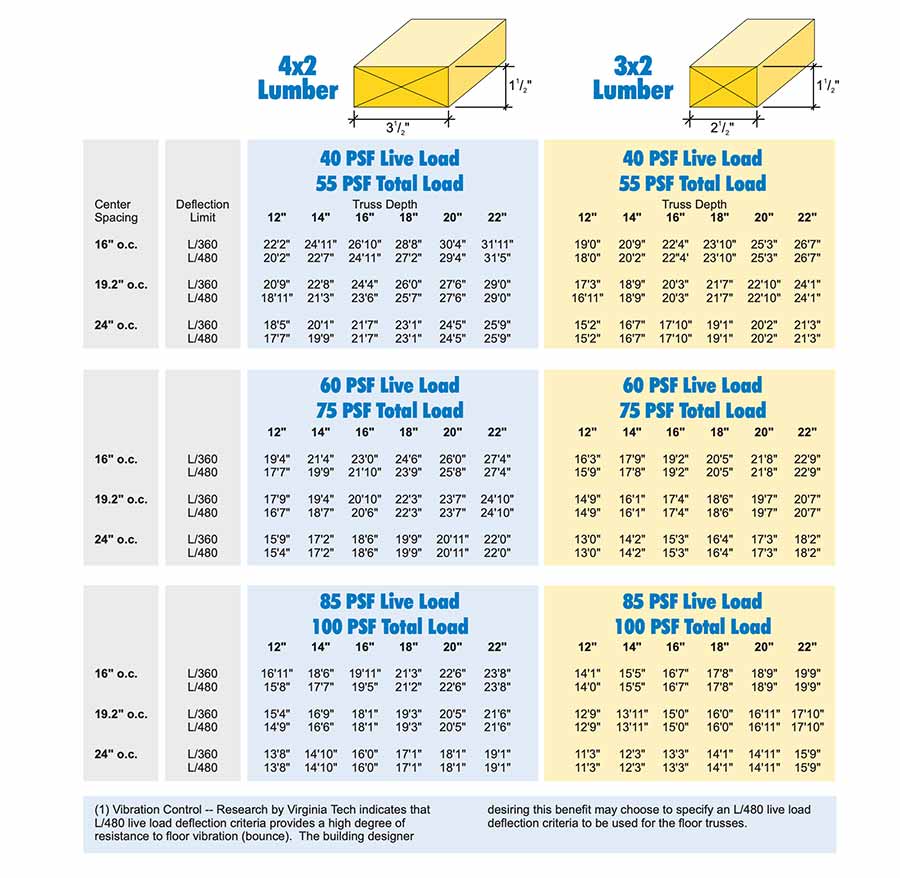

Using the most common variables, such as 16 inches between trusses, you can calculate the truss span, provided you know if the truss has 2×3 or 2×4 lumber. You’ll need to check with the truss manufacturer for a product manual that will outlay the specifications.

The length of the floor truss is referred to as the span. The L/480 table for 4×2 lumber, which has a 40 pound per square foot live load and a 20 pound per square foot dead load with a depth of 12 inches, will provide spans 20’2″ while truss depth of 22 inches can span 31’5″.

The L/480 table for 3×2 lumber, which has a 40 pound per square foot live load and a 20 pound per square foot dead load with a depth of 12 inches, will provide spans 18′ while truss depth of 22 inches can span 26’7″.